Recently, Australian researchers detailed their new medical 3D printing technique. The goal? Print bones directly in the body of patients using ceramic ink combined with living cells.

In the medical field, 3D printing is not new. One example is the world's first-ever double hand and face transplant largely made possible by 3D printing. In their report published in the journal Advanced Functional Materials, researchers from the University of New South Wales (Australia) unveiled a new ceramic ink for printing bones. The main characteristic of this ink is to incorporate living cells in the structure of the bones . However, these cells can multiply for several weeks after printing, with a viability of 95%.

Until now, 3D printing of bone tissue integrated synthetic components or foreign bodies to be introduced into the body. With their innovation, Australian scientists can directly imprint the bone in their patient's body while avoiding the use of potentially harsh chemicals.

“ It could be used in clinical applications where there is a high demand for in situ repair of bone defects such as those caused by trauma, cancer or when a large piece of tissue is resected” , can we read in a press release.

The video at the end of the article explains how this new ceramic ink works. According to project manager Kris Kilian, this innovation will save time during operations surgeries while reducing patient pain. He also explains that this unprecedented technique will save many lives. Remember that doctors usually use autologous bone graft to repair damaged bones. However, this method involving the removal of bone from another part of the body is particularly invasive. This can also pose a significant risk of infection.

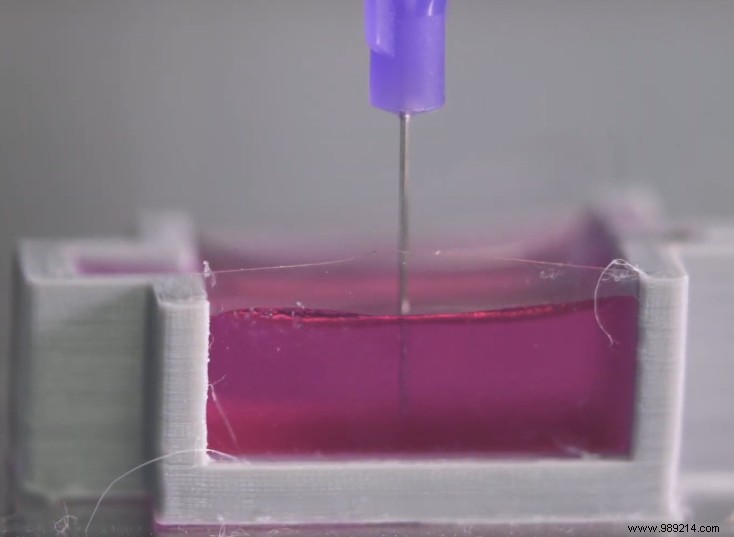

The ceramic ink in question is a biocompatible calcium phosphate as a paste at room temperature. Upon contact with a gelatin bath, the ink becomes a porous nanocrystalline matrix similar to normal bone tissue. This innovation could revolutionize medical 3D printing and allow the latter to occupy an even more important place in this field.

Here is the video published by the University of New South Wales: